Aseptic Process Simulation

Validating Aseptic Processing through Aseptic Process Simulation (APS)

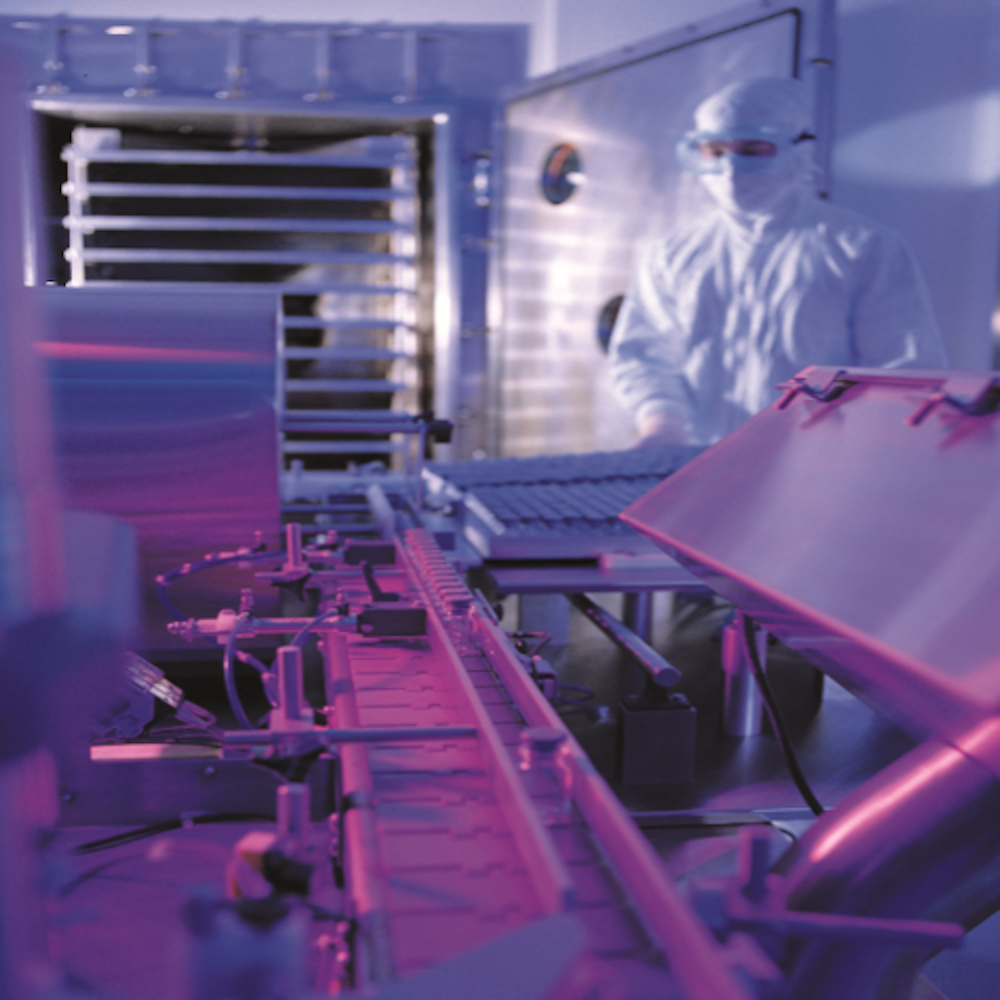

Aseptic Process Simulation (APS), commonly known as a media fill, plays a pivotal role in sterile manufacturing validation. This simulation, endorsed by regulatory bodies such as the FDA (2004) and EMA (2022), involves replacing the actual product with microbiological growth media. By doing so, it allows manufacturers to evaluate whether the aseptic process and operator techniques can effectively prevent microbial contamination under both normal and challenging conditions. Moreover, this proactive approach ensures that aseptic manufacturing environments remain compliant, resilient, and ready for commercial production.

Purpose and Scope of Aseptic Process Simulation

The core objective of an Aseptic Process Simulation is to replicate the entire sterile manufacturing process under the most challenging, worst-case conditions. This simulation takes a risk-based approach to assess how environmental controls, personnel behavior, equipment operation, and container closure systems influence sterility. In fact, by pushing the process to its limits, manufacturers can prove the robustness of their systems. A successful APS provides strong evidence that the process can consistently yield sterile product batches, even under less-than-ideal circumstances. This builds trust, enhances compliance, and reduces the likelihood of product recalls or regulatory issues.

Choosing the Right Growth Media

Selecting an appropriate growth medium is essential for the success of any Aseptic Process Simulation. The medium must be non-selective and capable of supporting a wide variety of microorganisms, including aerobic bacteria, yeasts, and molds. Soybean-Casein Digest Medium (SCDM), also known as Tryptic Soy Broth (TSB), is the most commonly used option. It is recognized by global pharmacopeias and offers broad-spectrum growth support. By using such a medium, manufacturers ensure that potential contamination is detectable during the simulation phase.

Designing and Repeating Media Fill Runs

To ensure reliability, an Aseptic Process Simulation must be repeated across multiple runs. Typically, a standard qualification includes three consecutive successful media fills conducted on different days.

Two of these runs should use the largest container size with the widest opening, since this setup increases exposure to environmental risks. The third run should involve the smallest container at the highest line speed, which challenges both operator precision and equipment consistency.

This strategic variety helps demonstrate that the aseptic process can handle different operational stresses without compromising sterility. As a result, it strengthens confidence in the manufacturing setup and supports long-term compliance.

Incorporating Personnel Interventions

A realistic Aseptic Process Simulation must include both routine and non-routine operator interventions. These actions replicate real-life scenarios that could potentially introduce contamination into the process.

Routine interventions may include activities like glove changes, operator breaks, or removal of jammed vials. On the other hand, non-routine interventions simulate less frequent but riskier actions—such as glass breakage, equipment resets, or correcting misaligned containers.

Including these steps ensures that the simulation reflects actual production conditions. Moreover, every intervention must be documented and justified within the APS protocol to maintain transparency and regulatory alignment.

Defining the Right Batch Size

The number of units filled during an Aseptic Process Simulation must be statistically justified. Regulatory bodies like the FDA recommend filling between 5,000 to 10,000 units, especially for commercial-scale validations.

Meanwhile, EU GMP Annex 1 allows for flexibility based on the product’s actual batch size, as long as the quantity provides statistically significant assurance of sterility. Regardless of the region, the chosen batch size must meet predefined acceptance criteria to ensure reliability.

By aligning batch size with risk and production scale, manufacturers can produce data that accurately reflects real-world performance and maintains regulatory confidence.

Follow more of our services here

Explore Services

+971 56 636 0153

info@senuconsult.com

Have Any Questions? Contact us here

+971566360153 or

info@senuconsult.com